Hornoslezská společnost s.r.o.

machinery engineering

the company with a long tradition

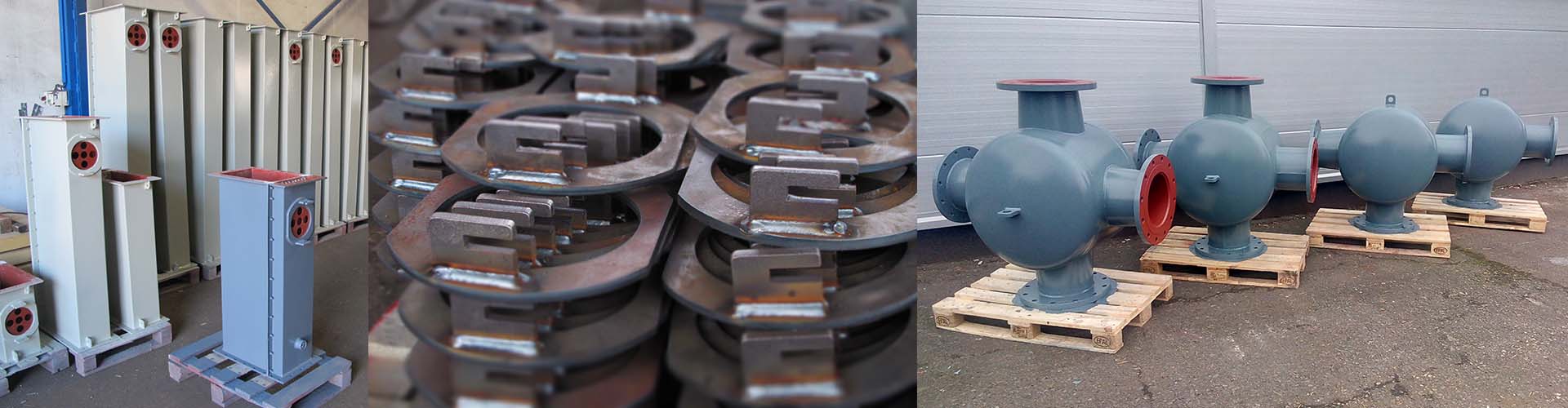

Our technology

The site of the company has a total surface area of some 1.5 hectares of land in Opava – Komárov. The crane site of the production area is 1700 sqm and the roof area is 500 sqm. We are equipped with a rich machine park. We have welding semiautomats and automatic machines, 2 robot welding workstations, 2 plasma CNC plasma cutting centers, 2 CNC and 1 mechanical bending press (80, 160, 315 t), 2 three cylindrical mechanical bending machines and one four cylindrical hydraulic CNC bending machine for the production of various cylindrical or conical pipes and hoppers, eccentric presses with a capacity of 25 to 100 tons of pressure, and many other powerful machines and equipment such as lathes, milling machines, radial drills, machine shears, etc., which modern operation cannot do without.

Our company employs 40 specialists, has its own design and construction department, which provides production documentation including modernization of the production program.

Machinery engineering and production that we do: Custom metal fabrication, sheet metal rolling, cone rolling, cylinder rolling, asymmetrical shape rolling, sheet metal bending, cone bending, cylinder bending, locksmith, welding, bandsaw cutting, material cutting, profile cutting, production of steel constructions, weldments for machining, painting, CNC sheet metal processing, sheet metal CNC plasma burning, CNC laser burning of sheet metal, manual plasma cutting, CNC laser cutting of L-profiles, CNC laser cutting of tubes, CNC laser cutting of steel bars, robotic welding, MIG/MAG welding, TIG welding, MMA welding, pressing.

Paintshop

We have our own varnished heated cabin of sizes up to 7,1x3,8x2,9m (lenght x height x width), where we perform so-called painting a wet way on pre-adjusted metal surface using high pressure Airless technology.